- Introduction

- Brief history of car design evolution

- Importance of materials in shaping car design

- Early Car Design: The Role of Wood

- The first automobiles and the use of wooden frames

- Why wood was the material of choice in the beginning

- The Transition to Steel: The Rise of the “Modern” Car

- How steel revolutionized car design in the early 20th century

- The benefits and limitations of steel

- Streamlined Steel: Design Advances in the 1930s and 1940s

- The influence of aerodynamics on steel car bodies

- The role of steel in iconic car designs

- Post-WWII: The Dawn of More Advanced Materials

- The influence of World War II on material innovation

- The first steps toward using aluminum in car design

- The Introduction of Aluminum in the 1950s and 1960s

- How aluminum was first used in car bodies

- Benefits of aluminum in terms of weight reduction and performance

- The Role of Plastics in the 1970s and 1980s

- The emergence of plastics in car design

- How plastics affected both design and production processes

- Carbon Fiber: The Next Frontier in Car Design

- Introduction to carbon fiber in the 1990s

- Why carbon fiber became a game-changer for high-performance cars

- Aluminum vs. Carbon Fiber: Which Material Wins?

- A comparison of aluminum and carbon fiber in modern cars

- Pros and cons of each material for different types of vehicles

- Sustainability and the Future of Car Materials

- How the push for sustainability is influencing material choices

- The rise of alternative materials like recycled composites

- Technological Advancements in Manufacturing

- How manufacturing methods have evolved alongside material innovations

- The role of technology in improving material performance

- The Impact of Car Design on Safety

- How material evolution has contributed to car safety

- The relationship between lightweight materials and crash protection

- Classic Cars and the Legacy of Early Car Design

- The lasting appeal of wooden and steel cars

- How classic car collectors are preserving vehicles from the past

- Future Trends: What’s Next for Car Design?

- What materials might dominate future car designs

- The possibility of fully sustainable car manufacturing

- Conclusion

- Recap of the evolution from wood and steel to aluminum and carbon fiber

- Reflection on how car design continues to evolve with new materials

- FAQs

- What is the most common material used in modern car design?

- How did aluminum change the automotive industry?

- What are the main benefits of carbon fiber in car construction?

- Why did cars use wood in the early stages of automotive design?

- Will future cars be made of entirely sustainable materials?

The Evolution of Car Design: From Wood and Steel to Aluminum and Carbon Fiber

Introduction

Car design has come a long way since the first automobiles rolled off the assembly line. In the early days, the materials used in car construction were simple and relatively limited, but over time, technological advancements and the need for more durable, efficient vehicles led to a complete overhaul in how cars were built. Today, car manufacturers use advanced materials like aluminum and carbon fiber, which have revolutionized the automotive industry. Let’s take a look at how the evolution of materials, from wood to steel, and then to aluminum and carbon fiber, has shaped the cars we drive today.

Early Car Design: The Role of Wood

In the earliest days of the automobile industry, car design was heavily influenced by the materials available and the limited manufacturing capabilities. The first automobiles, like the Benz Patent-Motorwagen (built in 1885), featured wooden frames and wheels, making use of the materials that were both accessible and easy to shape.

Wood was a preferred material because it was lightweight, easy to work with, and readily available. Early car designers utilized wooden bodies to create the first vehicles, and it wasn’t uncommon to see wood as a structural material in both the frame and the wheels. Of course, wood had its limitations—mainly in terms of durability and strength—but it served its purpose well in the initial stages of car development.

The Transition to Steel: The Rise of the “Modern” Car

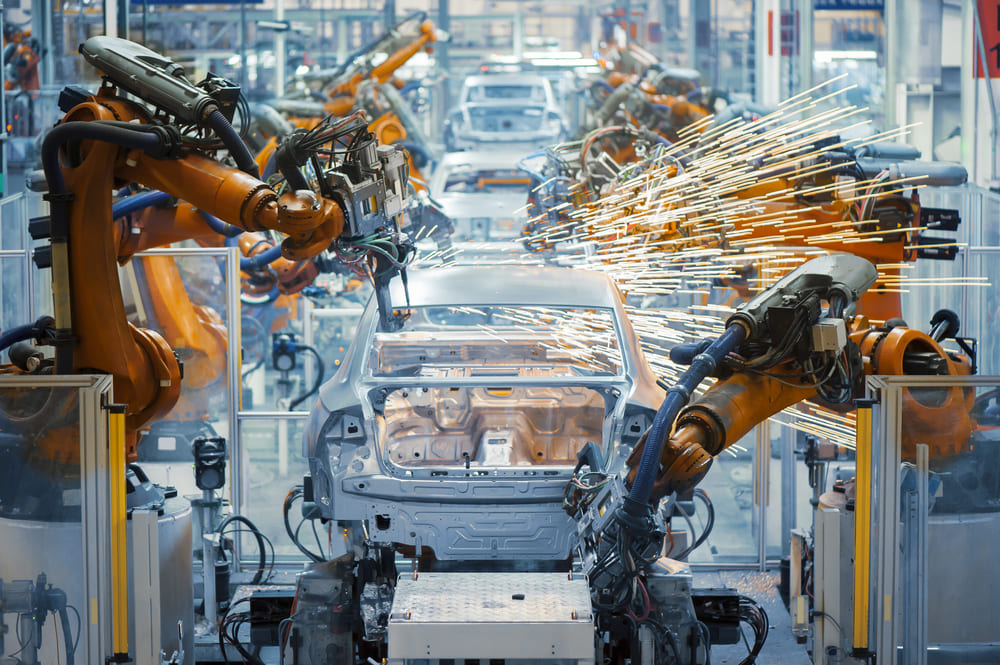

As the automotive industry began to expand, so too did the need for stronger, more durable materials. The shift from wood to steel was one of the most significant changes in car design during the early 20th century. Steel provided a much stronger material for the body of the vehicle, making cars safer and more reliable.

Steel frames allowed for more complex designs and offered a much higher level of durability. Additionally, the mass production techniques pioneered by Henry Ford helped make steel more affordable and accessible. Steel allowed for more streamlined and efficient car designs, marking the beginning of the “modern” car era.

Streamlined Steel: Design Advances in the 1930s and 1940s

In the 1930s and 1940s, the automotive industry began to focus more on aerodynamics and efficient designs. During this period, steel bodies became more streamlined, and manufacturers used advanced techniques to reduce drag and improve performance. This era saw the rise of some iconic car designs, including the Chrysler Airflow and the Ford V8.

The use of steel in these designs allowed automakers to build cars that were not only more functional but also more aesthetically pleasing, setting the stage for the stylish designs that would come in the post-war era.

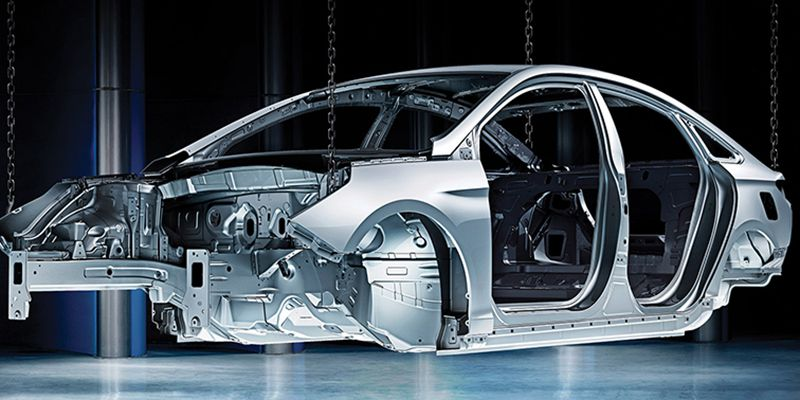

Post-WWII: The Dawn of More Advanced Materials

After World War II, the automotive industry began exploring new materials to further improve vehicle performance and reduce weight. Manufacturers were now able to experiment with materials like aluminum, which was lighter than steel and had better corrosion resistance. The use of aluminum became particularly popular for components like engine blocks, wheels, and body panels.

The post-war period marked the beginning of significant material innovation, which would continue into the next several decades.

The Introduction of Aluminum in the 1950s and 1960s

Aluminum made its first major appearance in car design during the 1950s and 1960s. The lightweight nature of aluminum allowed manufacturers to reduce the overall weight of cars, improving fuel efficiency and handling. Aluminum was also much more resistant to rust compared to steel, which was a significant advantage for cars operating in harsh weather conditions.

One of the most famous early uses of aluminum was in the production of the Chevrolet Corvette, which featured an aluminum body that contributed to its high performance. As demand for lighter, faster cars grew, aluminum became a key material in high-performance and luxury vehicles.

The Role of Plastics in the 1970s and 1980s

In the 1970s and 1980s, plastics started to play a bigger role in automotive design. Car manufacturers began using plastic components for interior parts, dashboards, and even body panels. Plastics were cheaper to produce, more flexible, and could be molded into intricate shapes, which made them an attractive option for automakers looking to streamline production processes.

Plastics also provided opportunities for cars to be more customizable, with different color options and trim finishes becoming increasingly popular.

Carbon Fiber: The Next Frontier in Car Design

The 1990s and 2000s saw the introduction of carbon fiber, a material known for its incredible strength-to-weight ratio. Carbon fiber quickly became the material of choice for high-performance and racing vehicles, as it offered a significant weight reduction without sacrificing strength. The use of carbon fiber in cars such as the McLaren F1 and Ferrari Enzo set the stage for a new era of automotive design, where performance and speed were paramount.

Carbon fiber is used primarily in the construction of the body and chassis of high-end sports cars. Although it’s expensive to manufacture, its performance benefits make it indispensable for cars built for speed and agility.

Aluminum vs. Carbon Fiber: Which Material Wins?

While both aluminum and carbon fiber have their advantages, they cater to different needs in the automotive industry. Aluminum is more affordable and easier to work with, making it the preferred material for mass-produced vehicles. It’s widely used in everything from sedans to trucks, offering a great balance between weight reduction, strength, and cost.

On the other hand, carbon fiber is the go-to material for luxury, sports, and racing cars, where performance is the priority. Carbon fiber is incredibly light and strong, offering superior durability and energy absorption, but its cost and complexity make it less suitable for mass production.

Sustainability and the Future of Car Materials

As sustainability becomes an increasingly important focus, the automotive industry is exploring new materials that are both eco-friendly and performance-driven. Recycled composites, bio-based plastics, and even hemp-based materials are being investigated as alternatives to traditional metals and plastics. The goal is to reduce the environmental impact of car production while maintaining high standards of performance and safety.

Technological Advancements in Manufacturing

Advancements in manufacturing technology, including 3D printing and advanced molding techniques, are also revolutionizing how materials are used in car design. These technologies allow for more precise production, greater flexibility in design, and less waste, all of which contribute to the efficiency and sustainability of car manufacturing.

The Impact of Car Design on Safety

Material evolution has also had a significant impact on car safety. The introduction of lightweight materials like aluminum and carbon fiber has not only improved performance but has also contributed to making cars safer. These materials are designed to absorb energy in the event of a crash, reducing the risk of injury to passengers.

Classic Cars and the Legacy of Early Car Design

While modern materials dominate today’s car designs, there’s still a special place for classic cars made from wood and steel. These vehicles are highly valued by collectors and enthusiasts who appreciate the craftsmanship of early car design. Restoring these cars to their former glory is a way of preserving automotive history for future generations.

Future Trends: What’s Next for Car Design?

Looking ahead, we may see more experimentation with alternative materials, such as graphene, which offers extreme strength and lightness. The push for fully sustainable, electric vehicles will likely drive further innovations in materials science, leading to cars that are lighter, stronger, and more environmentally friendly.

Conclusion

The evolution of car design has been an incredible journey, from the early use of wood to the modern applications of aluminum and carbon fiber. These materials have not only shaped how cars are built but have also influenced their performance, safety, and aesthetics. As technology continues to advance, it’s clear that the materials of the future will continue to drive the next generation of automotive innovation.

FAQs

1. What is the most common material used in modern car design?

Aluminum is widely used in modern car design for its strength, lightweight properties, and resistance to corrosion.

2. How did aluminum change the automotive industry?

Aluminum allowed for lighter, more fuel-efficient cars and became especially important in high-performance and luxury vehicles.

3. What are the main benefits of carbon fiber in car construction?

Carbon fiber offers an incredibly high strength-to-weight ratio, making it ideal for performance vehicles where weight reduction is critical.

4. Why did cars use wood in the early stages of automotive design?

Wood was one of the most readily available materials at the time and was easy to work with for early car manufacturers.

5. Will future cars be made of entirely sustainable materials?

While it’s uncertain, the automotive industry is actively exploring eco-friendly materials such as recycled composites and bio-based plastics to create more sustainable vehicles.